Asheville, North Carolina, a city of about 90,000 in the Blue Ridge Mountains, is a cultural hub, packed with dozens of art galleries and a thriving local music scene with venues that attract acts from around the world. So if there’s a pairing of a company and a community that works better than Moog Music and Asheville, I don’t know what it could be.

Asheville has been called one of America’s greatest music cities, and Moog wouldn’t dream of moving anywhere else. “We’ve really taken on a character of the town,” says Mike Adams, president of Moog Music, a 20-year veteran of the storied synthesizer company. “There’s a great music scene here, and there’s a lot of very artistic people. I would say 70% of the people that work here are musicians — it’s a really natural fit.”

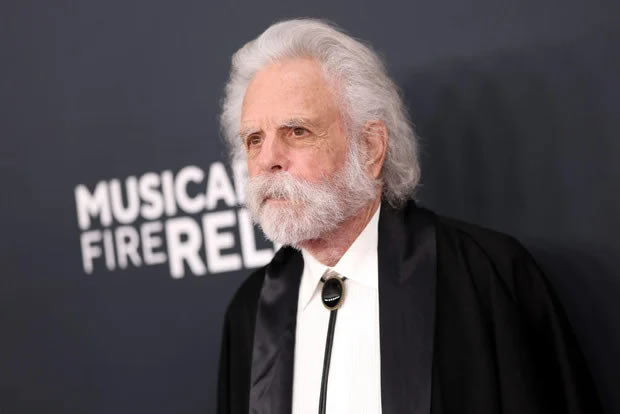

Moog’s high-end boutique synthesizers run keen shoes from around $1,200 to $9,000 or more. Founded in New York in 1953 by Robert Moog (pronounced “moag”), its instruments ushered in the era of electronic music, and have been used by everyone from Trent Reznor to Donna Summer, from The Beatles to the Beastie Boys. Today the factory where its 170 employees work looks more like a mad scientist’s music lab than an assembly line. And there’s a good reason: Each synthesizer takes dozens of hours each to build, all right in Asheville.

“Nothing we make has an off-the-shelf component to it,” Adams says. “And that’s part of the beauty.”

Founder Bob Moog moved to Asheville in 1978, and the company has been making synths here since 1994. Its ability to attract the unique mix of musical know-how and the technical skills required to assemble the synths is another reason Moog is staying put. Adams mentions at least two current employees who drove to Asheville, prepared to live out of their vans until they could somehow get hired at the company.

“We obviously have to attract and recruit specific engineering talent,” he says. “But there’s a lot of people [here] that have just always loved what Moog is about and what it stands for.”

Despite a premium product line and fiercely loyal customers, Moog faces a lot of the same manufacturing challenges as other businesses around the world. “Supply, supply, supply.”

“We just can’t get enough parts to keep up with the production,” Adams says. “We’ve been hurt by the extraordinary expense that it’s taken to bring in material that’s cost us an arm and a leg.”

The supply chain problems stem from the COVID-19 pandemic, nike outlet which hasn’t left the rarified world of hand-assembled synthesizers untouched. While Moog instruments are built in the USA, critical internal components come from China, which leaves this company in the same difficult situation as so many others. Factory shutdowns and slowdowns around the world have left some components in short supply, driving up prices, while international cargo shipping is struggling to catch up on missed 2020 deliveries. It’s a version of the same problem plaguing phone manufacturers and carmakers. It’s the same reason you still can’t buy a PlayStation 5. Even the price of the wood used on the outer shells of retro-looking Moogs has skyrocketed.

“Our business is really handcuffed by our suppliers and the ability to get anything from plastic to metal to electronic components to printed circuit boards,” says Adams.”The reasons for that range from anything from raw materials shortages to climate change to COVID to just a huge spike in demand for certain products.”

But there’s something of a pandemic silver lining for a company like Moog, too. Spending more time at home, those with the means to do so took the opportunity to invest in hobbies and creative pursuits that mattered to them. And by not spending money on travel or entertainment, some spent more skechers outlet than they normally would on things like premium music gear.

“People did the cocooning, and they wanted better gear because they’re spending so much more time with it,” says Joe Richardson, Moog’s chief marketing officer. “Our instruments lend themselves very well to folks creating music on their own. There was so little performing going on, so synthesizers make for a great way to discover and go exploring to satisfy that creative need.”

Despite the supply chain and pandemic challenges, the company says it has sold twice as many of its flagship (read: $9,000) Moog One synths as expected so far in 2021.

“It’s a really strong statement that people are willing to invest in quality,” Richardson says, adding, “Nobody buys a Moog because it’s inexpensive.”

The handcrafted look of a Moog, and the unique factory where the instruments are built and tested, are all part of the brand’s mystique. CNET photographer Sarah Tew took a tour of Moog’s Asheville headquarters. Follow along with her to see everything from vintage synths to testing stations to a display case of rare prototypes. And when you’re in Asheville, you can take a mini tour (more extensive tours are suspended due to the pandemic) and browse the company store and a showroom. A separate “Moogseum” nearby is run by the Bob Moog Foundation, named after the company founder, who died in 2005.

+ There are no comments

Add yours